Niobium Wire

Description

R04200 -Type 1, Reactor grade unalloyed niobium;

R04210 -Type 2, Commercial grade unalloyed niobium;

R04251 -Type 3, Reactor grade niobium alloy containing 1% zirconium;

R04261 -Type 4, Commercial grade niobium alloy containing 1% zirconium;

Type and Size:

Metallic impurities, ppm max by weight, Balance - Niobium

| Element | Fe | Mo | Ta | Ni | Si | W | Zr | Hf |

| Content | 50 | 100 | 1000 | 50 | 50 | 300 | 200 | 200 |

Non-Metallic impurities, ppm max by weight

| Element | C | H | O | N |

| Content | 100 | 15 | 150 | 100 |

Mechanical properties for annealed wires 0.020in(0.508mm)-0.124in(3.14mm)

| Ultimate Tensile Strength (MPa) | 125 |

| Yield strength (MPa, 2% offeset) | / |

| Elongation(%, 1-in gage length) | 20 |

Dimensional Tolerance for Rods and Wires

| Diameter in (mm) | Tolerance in (±mm) |

| 0.020-0.030(0.51-0.76) | 0.00075(0.019) |

| 0.030-0.060(0.76-1.52) | 0.001(0.025) |

| 0.060-0.090(1.52-2.29) | 0.0015(0.038) |

| 0.090-0.125(2.29-3.18) | 0.002(0.051) |

| 0.125-0.187(3.18-4.75) | 0.003(0.076) |

| 0.187-0.375(4.75-9.53) | 0.004(0.102) |

| 0.375-0.500(9.53-12.7) | 0.005(0.127) |

| 0500-0.625(12.7-15.9) | 0.007(0.178) |

| 0.625-0.750 (15.9-19.1) | 0.008(0.203) |

| 0.750-1.000 (19.1-25.4) | 0.010(0.254) |

| 1.000-1.500 (25.4-38.1) | 0.015(0.381) |

| 1.500-2.000 (38.1-50.8) | 0.020(0.508) |

| 2.000-2.500 (50.8-63.5) | 0.030(0.762) |

Features

Grade:RO4200,RO4210

Purity: 99.95%(3N5)-99.99%(4N)

Manufacturing Standard: ASTM B392-99

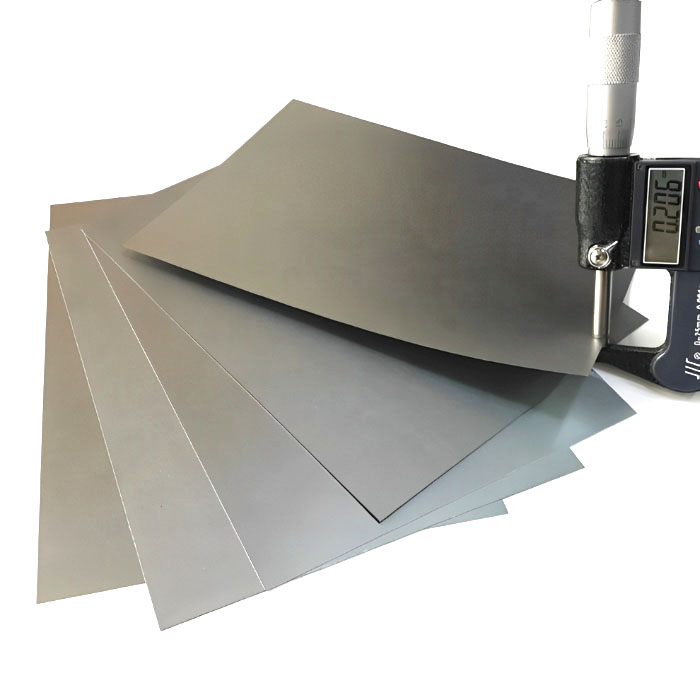

Surface: should be smooth, clean, greaseless, without fissure or burr, no mess around, no knotting, no crossover, no continuous pitches or scratches.

Applications

To manufacture niobium mechanical parts, electric materials, high voltage sodiumlamp and Jewelry; widely applied for pharmacy, semiconductor, aviation and aerospace, nuclear, high temperature assemblies and other fields.