Molybdenum Lanthanum (MoLa) Alloy Sheets

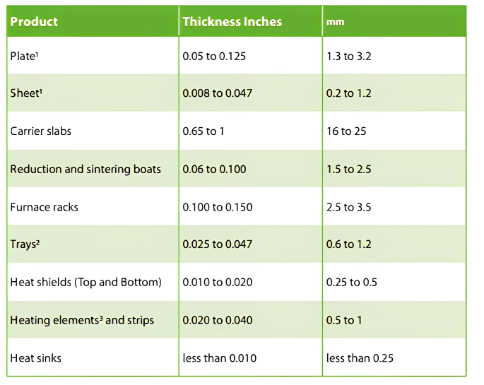

Type and Size

Features

0.3 wt. % Lanthana

Considered a substitute for pure molybdenum, but with longer life due to its increased creep resistance

High malleability of thin sheets; the bendability is identical regardless, if bending is done in longitudinal or transverse directions

0.6 wt. % Lanthana

Standard level of doping for the furnace industry, most popular

Combines the widely accepted high temperature strength with creep resistance – considered the “best value” material

High malleability of thin sheets; the bendability is identical regardless, if bending is done in longitudinal or transverse directions

1.1 wt. % Lanthana

Strong warpage-resistance

High strength properties

Exhibits the highest creep resistance of all offered grades

Applications for formed parts require recrystallizing anneal cycle

Applications

Molybdenum lanthanum alloy plate is used for producing tungsten and molybdenum electrodes, heating elements, heat shield, sintered boat, folded plate, bottom plate, sputtering target, electronics and crucible for vacuum. La2O3 is contained in MoLa plate to prevent molybdenum grain’s wrong movement and re-crystallization of slow rhythm under high temperature. The usability of molybdenum lanthanum plate and service life has been improved greatly. The surface of MoLa alloy plate we produce is smooth, no level, no lamination, no crack or impurities.