Molybdenum Heat Shield&Pure Mo screen

Description

Molybdenum heat shielding parts with high density, exact dimensions, smooth surface, convenient-assembly and reasonable-design has great significance in improving the crystal-pulling. As the heat-shield parts in the sapphire growth furnace, the most decisive function of molybdenum heat shield (molybdenum reflection shield) is to prevent and reflect the heat. Molybdenum heat shields can also be used in other prevent heat needs occasions.

Molybdenum heat shields are mostly made from molybdenum sheets by welding and riveting, molybdenum rods, molybdenum nuts and molybdenum screws are also used to make molybdenum heat shields. We provide molybdenum heat shields per customer’s drawing.

Type and Size

Molybdenum Heat shields can be made any size and configuration. Dimensions and tolerances are according to your drawings. High-quality molybdenum products provide exceptional heat resistance. Price of molybdenum heal shield depends on size, complexity, configuration, and additional requirements specified in the order.

|

Molybdenum Lid |

Molybdenum Heat Shield |

|||

|

Thickness |

Dia (max) |

Thickness |

Dia (max) |

Height (max) |

|

2.0 ± 0.1 |

660 ± 0.2 |

2.0 ± 0.1 |

450 ± 2 |

660 ± 1 |

|

1.0 ± 0.08 |

660 ± 0.2 |

1.0 ± 0.08 |

610 ± 2 |

660 ± 1 |

|

0.5 ± 0.04 |

660 ± 0.2 |

0.5 ± 0.04 |

700 ± 2 |

660 ± 1 |

|

0.3 ± 0.03 |

660 ± 0.2 |

0.3 ± 0.03 |

700 ± 2 |

660 ± 1 |

Features

- Standard:ASTM B386, Type 361

- Mo≥99.95%

- Application temperature environment < 1900°C

- Linear thermal expansion coefficient is small

- Production and processing are relatively easy

- Thermal conductivity is low and specific heat is small

Applications

Molybdenum heat shields are used in high-temperature resistance furnaces and sapphire growth furnaces due to their ability to withstand high temperatures and corrosion.

Heat-shield parts have high density, exact measurement, and smooth surface, which make them excellent in improving crystal pulling.

Molybdenum heat shield is most commonly used in vacuum furnace.

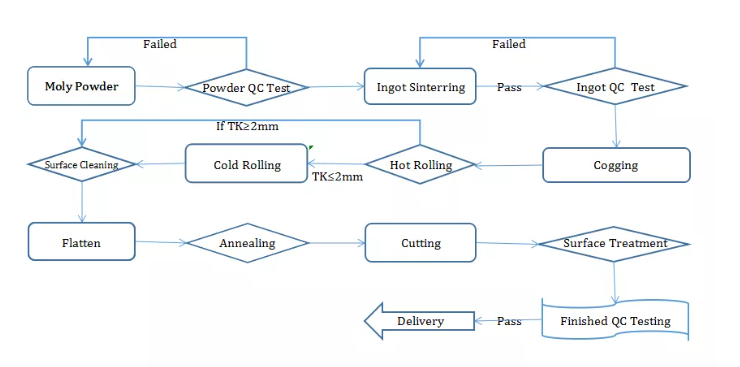

Process