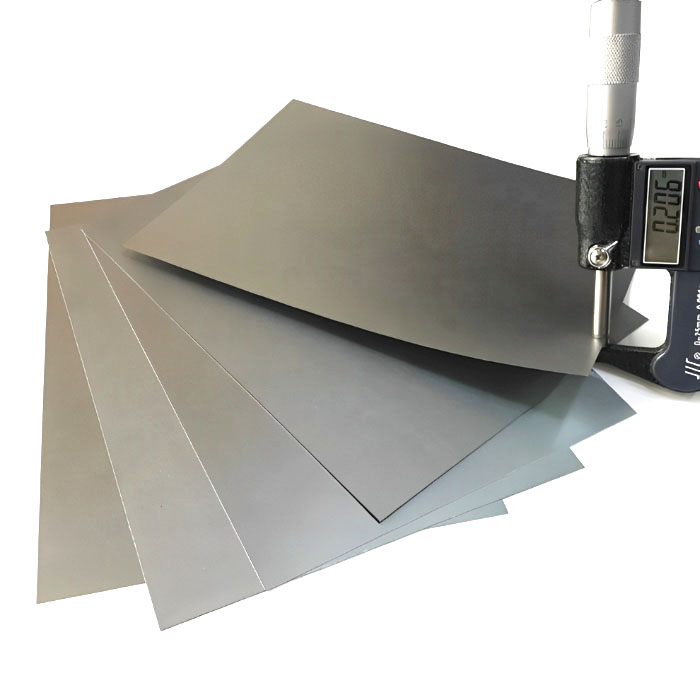

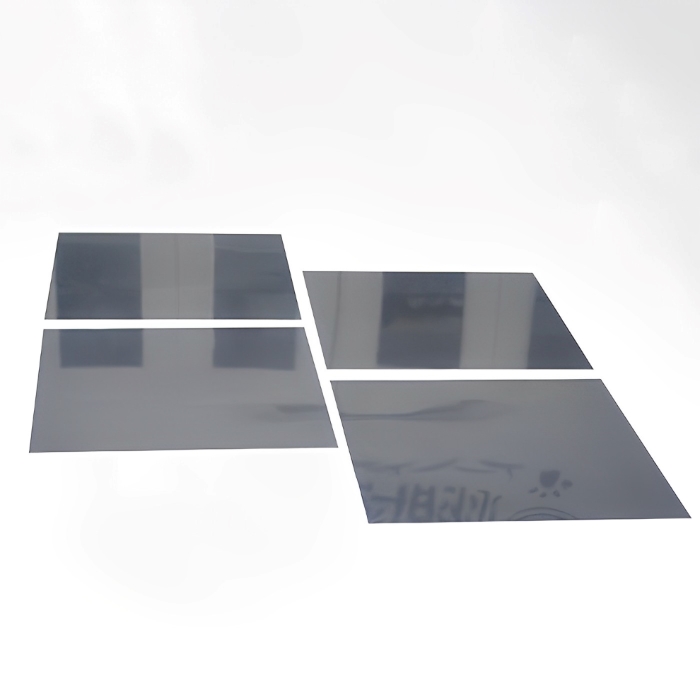

Hot Selling Polished Superconductor Niobium Sheet

Description

We produce R04200, R04210 plates, sheets, strips and foils which meet ASTM B 393-05 standard and the sizes can be customized as per your required dimensions. We will do our best to fulfill customers' needs and markets' demands by providing a great variety of customized products. Taking advantages of our high quality niobium oxide raw material, advanced equipment, innovative technology, professional team, we tailored your required products. You may tell us all your requirements and we dedicated in manufacturing upon your needs.

Niobium plate, sheet, strip and foil are manufactured by ASTM B391 niobium ingots.We smelt the high purity Nb2O5 we sourcing from the Chinese biggest hydrometallurgy plant by means of aluminothermic reduction to produce niobium aluminum alloy. Then the niobium aluminum alloy will be smelted in high Vacuum EB furnace to produce niobium bars with Nb content 99.9% up, which will be smelted again in high Vacuum EB furnace to be purified and produce Niobium ingots with purity 99.95% up.

Type and Size:

flat products with width≥6inch(152.4mm), thickness is between 0.005inch (0.13mm) and 0.1875inch (4.76mm);

Impurities

Metallic impurities, ppm max by weight, Balance - Niobium

| Element | Fe | Mo | Ta | Ni | Si | Ti | W | Zr | Hf |

| RO4200-1 | 50 | 100 | 1000 | 50 | 50 | 200 | 300 | 200 | 200 |

| RO4210-2 | 100 | 200 | 3000 | 50 | 50 | 300 | 50 | 200 | 200 |

Non-Metallic impurities, ppm max by weight

| Element | N | O | H | C |

| RO4200-1 | 100 | 150 | 15 | 100 |

| RO4210-2 | 100 | 250 | 15 | 100 |

Different specifictions availalbe unpon requests.

Mechanical properties for annealed strips and foils

| Ultimate Tensile Strength (MPa) | 125 | |

| Yield strength (0. 2% offset) min, psi (MPa) | 73 | |

| Elongation(%, 1-in gage length) | thickness ≥0.01in (0.254mm) | 20 |

| thickness <0.01in (0.254mm) | 15 | |

Dimensional Tolerance

| thickness (in) | 0.129-0.254 | 0.279-0.381 | 0.406-0.508 | 0.508-0.762 | ||

| tolerance on thickness (±mm) | W<152.4 | 0.0127 | 0.0178 | 0.0203 | 0.04 | |

| 152.4≤W<609.6 | 0.0254 | 0.0254 | 0.0381 | 0.06 | ||

| Tolerance on thickness (slit) (±mm) | W<152.4 | 0.305 | 0.381 | 0.381 | 0.51 | |

| 152.4≤W<609.6 | - | 0.381 | 0.381 | 0.64 | ||

| Torerance on length(±mm) | L≤340.8 | + | 1.59 | 1.59 | 1.59 | 1.59 |

| - | 0 | 0 | 0 | 0 | ||

| L>340.8 | + | 2.38 | 2.38 | 2.38 | 2.38 | |

| - | 0 | 0 | 0 | 0 | ||

Features

Niobium Sheets , 99.95% 3N5- 99.99% 4N Purity , ASTM B393-05

Material: RO4200-1, RO4210-2A

Standard: ASTM B392-98

Purity: Nb >99.9%, >99.95%

Applications

Mechanical stamping for Nb shells, containers etc. Used for chemical anticorrosion, capacitor parts, target material for optics industry, superconducting material, electrical light material, medical treatment, refrigeration, artificial diamond and alloy addition.